Explore The Magical World of Electric Irons

Scene from: Tarzan vs. KaKi, Universal, 1938

(l. to. r.: Vanessa Brown, Denise Darcel, Henry Forstner, Italo Calvino (with iron),Lex Barker, Ira Eaker, and Billy Rubin)

KaKi, Goddess of Mindless Tasks after the famous statue in Bhutol attributed to Chauvitupuras, c 1320

Exciting things are hiding in the laundry room...

Let's Take a Trip Inside Your Electric Iron!

For those of you who don't like buttons, here is a more analytical index to help you find your way to just what you're looking for.

- Theory and History of Ironing [This Page]

- Why Are We Doing This?

- Early Ironing

- Critical Dimensions of Ironing

- Mrs. Potts and the Sad Iron

- The American Beauty Iron

- The Pyrex Silver Streak Iron

- The Pettipoint Winged Iron

- Steam Irons

- The Iron Handle

- The Thermostat

- The Winstead-Singer Durabilt Travel Iron

- The Future

- Underwriters Laboratory Standards for Irons

- Starch - the Old Fashioned Way

- Etymology of the Dreaded "M" Word

- Replacement Cords for Appliances

- The Ironrite Ironer [Separate Page]

- Introducing The Ironrite

- The Ironrite Health Chair

- Oiling the Machine and All About that Special Ironrite Oil...

- Electrical Problems

- All About Motors

- Changing the Roll or Muslin on the Ironrite

- Ironrite Promotional Trinkets

- Ironrite Manuals Available for Free

- Help Us Find Louise!

- Ironrite Movies That You Can Watch

- The Built-In Ironrite

- Other Mechanical Ironers [Separate Page]

Join Us on Facebook

Why Are We Doing This?

Why would a grown man make a web page devoted solely to ironing?

No doubt, ironing occupies an important place in our society --- go to a job interview without a pressed shirt if you want a practical demonstration. But, there is actually a sociological reason for our ironing page. It all goes back to LIFE Magazine...

...particularly the November 25,1946 issue, which also marked the magazine's tenth anniversary. It seems that consumers were just a little bit antsy because Industry was taking a bit too long converting from war production to consumer goods. So, the folks at LIFE did a little piece on "The American Dream" that took the form of a two page photo showing a typical family (2.2 children...) posing with some of the consumer goods that were most desired.

LEFT:The American Dream in 1946Photograph by Bernard Hoffman

RIGHT: David Wallace's Patent (D 127,649) for the Chrysler Town and Country

Click to enlarge

Most of these desiderata are fairly mundane -- a dishwasher ($299), washing machine ($241), electric range ($266), and freezer chest ($200). A floor model radio/phonograph/television (at $1,795) represents American dreaming about home entertainment. [prices in 1946 dollars]

The background shows a upper scale suburban home, stone veneer, bay window, one car garage. The property line is apparently delineated with a split rail fence. Examples of this can be found in great numbers in the near suburbs, particularly in the Falls Church area.

The only item of the 1946 American Dream that has even approached immortality is the car: a 1946 Chrysler Town and Country convertible ($2,890 then, $150,000 now) is shown. This model, an extremely rare and expensive antique now, is distinguished by its use of wood trim --- it is not a wood-body car like older station wagons. Rather, it is a streamlined modern car with real wood trim. They are truly beautiful machines; click on the link to see for yourself! [It is unclear whether they wanted the Helicopter]

So, the bottom line on the Life picture is that the average American in the mid-Forties could have been bought off with less than $25,000 in consumer goods... [without the Helicopter]... Given these modest expectations, it is no wonder the Democrats managed to hang on to power for so long...

SO WHAT DOES THIS HAVE TO DO WITH !#&$*#&## IRONING?

One of the appliances pictured in the 1946 article is an IronRite ironer... known generally to the population as a "Mangle". (You can see why the Iron-Rite corporation is so emphatic about calling it an Ironer.) So, here is an up close look at a small piece of the American Dream

The IronRite Ironer

Freedom from the Dry Cleaner!

Click to Enlarge

The unraveling of why Ironing should be wrapped up in The American Dream has led me to write this page. The fact that I found one of these Iron-Rite machines at a yard-sale also helps. We have an elaborate discussion of the Ironrite and all its competitors below, but if you keep on scrolling, we have a lot of information on all kinds of irons that will help explain why an ironing machine was part of the American Dream.

So, for better or worse, here is a summary of Ironing in America. Along the way, we'll discover that it has roots in female emancipation, the growth of the consumer economy and even touches upon corporate scandal and the mass exporting of American jobs abroad. And you only thought that it was a tiresome household chore...

In the Beginning

Ironing works by loosening the bonds between the long-chain polymer molecules in the fibers of the material. While the molecules are hot, the fibers are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics (developed in or after the mid-twentieth century) are advertised as needing little or no ironing because their molecules have been designed to remain stable.

David Woodcock, Assistant Curator of Domestic Technology at the Science Museum of London, traced pressing back to the Egyptians and Romans who did not use heat, relying on weight and pressure alone to smooth cloth. "Hot Ironing" is a relatively new idea that apparently came from the Mysterious East.

Among the methods of pressing that do not involve heat are:

- Smoothing Stones, shaped like a large mushroom, are the earliest western ironing devices. In Scandinavia they are known as "slicken" stones, slekje meaning to polish and smooth. They were made from various hard materials such as wood, glass, stone and bone. One or two hands were used to press firmly down upon the fabric; by rubbing back and forth rapidly, the friction generated heat that assisted in smoothing. In parts of Holland they are still used to leksteen (polish and smooth) the starched parts of the National costume.

- The Smoothing Board or mangl is an improvement on the smoothing stone by using mechanical force to apply pressure. The fabric is wrapped around roller and a lever is used to apply pressure as the roller is turned. (This is the basis for advanced Ironing Machines, as discussed below. The difference is that heat was not applied)

- The Linen Press has two hard flat surfaces that are squeezed together by a threaded rod and flattens fabric placed between plates with pressure.

Somewhere around the 12th Century, East met West through trade. Fashion became heavily influenced by the possibilities of starching and pressing. Of note, people began to wear ruffled and fluted collars that demanded both Heat and Pressure. Among the earliest devices were:

- Goffering Irons are slender rods that were arranged on a stand. They were heated either with a flame or by inserting a heated core or "slug". Cloth was inter-threaded between the rods to form the ruff. This was a complex process and only the very wealthy could afford the time and labor associated with goffering. Consequently many of these devices are lavishly ornamented and are quite valuable to collectors.

- Fluter Irons represented the application of mechanics to the process of pressing. They can look like meshed sets of gears that crimp and press at the same time. Others look like large sets of pliers that form the cloth into a given shape by squeezing the handles. Others look like a mold -- a top piece is pressed into the bottom to shape the garment. There is a wide variety of these devices all keyed to separate fashion trends. Heat was supplied to the fluter by either inserting a hot slug or heating the device on a stove.

- Sad Irons (where sad means "heavy") are the rudimentary ancestor of all modern irons and evolved as a single tool to serve a wide variety of purposes.

By the 18th Century, irons had evolved to their current shape and size. The smoothly pointed shape facillitates the ironing of pleats, collars and small details. The notch in the nose allows you to iron around buttons. The weight is a compromise between heat retention and heft. A big, heavy iron will hold heat for a long time, but it will kill your arm if you use it for very long. In general, 2,000 years of trial and error gave us a device that is immediately recognized as an "iron."

Below is a group of irons from a variety of countries and time periods. They all look the same. This illustrates the dictum "Form Follows Function"

Irons from England, Germany, France, Turkey, and Japan

Early irons had to be heated with fire of some sort. Wood and coal fires were often used, but an intermediary device was required because the iron itself could not be exposed to the flame lest it be covered with soot or ashes and thereby dirty the clean clothes it was supposed to press. Most of the time, a stove made of steel or cast-iron was used to contain the fire, and the ironing implement rested on it. In some cases, the iron was made hollow and a hot "slug" of metal (that could be heated in an open fire) was inserted into it. Later, the "self-heating" iron came to include variations that used charcoal, kerosene, or white gas. Some of these are shown below:

Self-Heating Irons

(l. to r.: Kerosene, White Gas, Charcoal)

Please check out this website for an exhaustive collection of irons from all countries and historical periods. This is a marvelous collection and it is presented very well.

We have also seen irons that have a connection for a natural gas tap, and others that received live steam from a boiler. These types of irons were generally used in commercial applications and could be very dangerous. However, the efficacy of the steam pressing technique led to the development of safe home steam-irons. Until the 1980s, the Coleman corporation made irons, fueled with white gas, that were very useful in situations where electricity was not available.

For all of these irons, the appropriate temperature for ironing was judged by the user. Thermostatic controls would have to wait for a long while...

Dimensions of Ironing Technology

This brief review of History shows that four factors are important to ironing technology. The evolution of this technology will be viewed through representative inventions that address each of the factors:

- Weight: The iron must be heavy enough to compress the cloth but it cannot be so heavy that it limits the ability of the operator to use it.

- Heat Source: The iron must acquire heat energy from some source either from transference (slugs, stoves) or self-contained processes(combustion, or electrical resistance.)

- Heat Regulation: There must be a method for assuring that the heat of the iron lies within the minimum needed to press the cloth and maximum to prevent damage.

- Moisture: moist heat is most conducive to the effectiveness of pressing; moisture must be supplied from an external source (dampening, press cloth) or from within the iron (sprinkling or steam)

The evolution of ironing technology has involved removing the judgemental aspects of each factor and replacing them with automated decision-making. This opened ironing to the masses. Once the door was opened, people decided that it was a whole lot of work and social trends moved to doing away with ironing altogether through a combination of fabric treatments that reduced wrinkling and/or acceptance of unpressed garments

Mrs. Potts and the Sad Iron

In general, up to the middle of the 1800s, iron design was generally between the blacksmith and the consumer. There were a number of "flatirons" available commercially, but the process of improvement through invention was slow to take hold. All of this got a fairly rude jolt in 1871 when Mrs. Mary Florence Potts patented an improvement on the "Sad Iron." [remember that sad means "heavy" in this context] The handle on her invention was removable allowing the user to have many iron bodies heating on the stove. When one cooled, all you had to do was remove the handle and attach it to a fully heated iron.

The Legendary Mrs. Potts and Her Invention

Mrs. Potts Sadiron Patent, No. 113,668

Click to Enlarge

Click here if you want to learn how to get Patent Drawings

This is noteworthy for several reasons: First, it is a darned clever idea. Second, it is a major consumer product invented and patented by a woman (at the time, women could not vote...) Third, it reflects the growing mass-market for appliances. Mrs. Potts became famous because she advertised broadly. The Potts Patent Iron became one of the very earliest commercial successes in the growing post-Civil War economy. Mrs. Potts directed the company and was considered to be a very able executive.

Robert Caro provides a wonderful chapter on the difficulties faced in the process of pre-electric ironing in his chapter on "The Sad Iron" in the first volume of his monumental biography of Lyndon Johnson (Lyndon Johnson: The Path To Power); in this chapter, Mr. Caro provides an appraisal of life before and after the Rural Electrification Administration brought cheap power to the farmers of the Hill Country in Texas. President (then Congressman) Johnson was one of the prime movers in this government program.

"...Three to six irons, each rubbed with beeswax and wiped before each use, stayed hot on a piece of sheet iron set on a hearth free from cinder or ashes, and later on the stove. Every iron fresh from the fire had to be tried on a piece of paper or spare cloth to be sure that it would not scorch the cloth. Large articles were ironed on tables, covered with a woolen ironing blanket and then a linen or cotton ironing sheet..."

Here is a photo of a "typical" kitchen in 1917 -- you'll note that the lady of the house is making some "artisanal" muffins in her earth-friendly wood stove. She must be a trend-setter because she does have a gas burner. Alongside that, we present an article from Popular mechanics that shows a clever way to form beeswax for use in ironing.

"Artisanal" Kitchen Circa 1917

Preparing Beeswax for Ironing, Popular Mechanics May, 1934

Click to Enlarge

The "One Size Fits All" handle enabled the user to select the iron that met the needs of the task (i.e a large iron for flats or a small iron for cuffs). The user could rapidly switch between irons as they cooled and were heated. However, the Potts invention did not address the problems of heat regulation and moisture -- factors that were left to the judgement of the user. In novices, these could have disastrous results such as scorches, burns, and fires. For the time being, ironing remained a boring and dangerous job, Mrs. Potts notwithstanding. The bright side was that you could do a whole lot more of this boring and dangerous task in the same amount of time.

The American Beauty Iron

The Electric Iron marks the beginning of a consumer revolution that lessened the burden (somewhat) on the American housewife who was largely responsible for the drudgery of laundry. For this discussion, we are going to focus on the American Beauty Iron as a representative of a whole class of electric irons.

The American Beauty Iron

H.W. Seeley Patent No. 259,064

Click to Enlarge

The American Beauty was NOT the first electric iron. On June 6, 1882 by Henry W. Seely of NYC patented the "electric flatiron" and used a carbon arc to create heat --- a thoroughly unsafe technology.

The Seely iron weighed 15 pounds and took a very long time to warm up. It is of some note that Mr. Seely assigned his patent to Samuel Insull the utility tycoon who would later be indicted for major fraud in selling securities in the electricity industry.

In 1892, hand irons using much safer electrical resistance technology were introduced by Crompton and Co. and the General Electric Company, and this has been the standard ever since. This iron had an electric heating element in the base and a somewhat traditional hand-held chunk of metal on the top. Later "irons" would have the heating elements built in to the hand-held tool. The adavantage was that the thing always stayed hot. The disadvantage was the cord. However, the two-piece irons like the "Boudoir" had a definite advantage over the older method --- electric heat kept the iron clean. If you heated your iron on a wood stove, it could easily get dirty and ruin the clothes that were being pressed. This iron is particularly valuable because the collector has retained the original box! This probably dates from the World War I era.

The Boudoir Iron

Click to Enlarge

However, the Underwriter's Laboratory [see below] considers the American Beauty Iron to be "the first mass consumer electric appliance..."

The American Beauty iron is a symbol of the decline of American Manufacturing. The irons were manufactured in Detroit from about 1912 to 1995. The architecture of the factory was quite noteworthy and was the study of an award-winning film called American Beauty Ltd. made by the German director, Dieter Moeller. (This should not be confused with a film with similar title starring Kevin Spacey)

Here is a photo of the American Beauty Factory. It is as difficult to conceive of a manufacturer today building such richly appointed factories. The abandoned American Beauty Electric Irons factory sits on Woodward just south of Grand Boulevard in Detroit. Behind it can be seen the tower of the Fisher Building and part of the former General Motors headquarters, long abandoned, reaffirming the thesis that today the only things that Americans make are lawsuits and hamburgers.

The American Beauty Factory

The American Beauty is NOT the most beautiful iron ever made, either. For that honor, I would nominate the Silver Streak made out of Pyrex glass by the Corning Company.

The Ultra-rare Silver Streak Glass "Irons"

Click to Enlarge

Because they were made out of glass, these implements are extremely rare (to say the least...)

Others, including our friends "40s Phil" and "Acme Ron" would lean to the winged Pettipoint Iron as the most distinctive iron of the period:

A Pair of Winged Pettipoint Irons

Stevens and Schreyer Design Patent D 128,629

Click to Enlarge

Click here if you want to learn how to get Patent Drawings

Ron has the following to say about these irons:

"... If you hold them sideways, you can see straight through the 'cooling fins'. The point at the back was for pleats. ..."

The Pettipoint Iron was designed by Clifford B. Stevens and Edward Schreyer in about 1941:

Back to the American Beauty Iron...

On the other hand, the American Beauty has its share of admirers. Both the Baltimore Art Museum and the Museum of Modern Art include the American Beauty Iron in their collection of exemplars of the best in 20th Century Design. Of note is the fact that a very large number have survived intact, something that cannot be said for their graceful Pyrex competitors.

In addition to the fact that it is historic, attractive, and durable, I have chosen the American Beauty Iron because I own two of them. I actually use these irons on a weekly basis and they still work perfectly. Not only that, I have all the patent drawings for them so I can illustrate how the various components work. The concepts used in the American Beauty are completely transferable to almost every other iron. Last week a friend's Rowenta Iron (c. 2003) broke down; I was able to disassemble it and fix it within short order because it is exactly the same inside as the American Beauty!

To add to my traditional ironing center, I found the "Wil-Stan" Iron holder at a yard sale. As shown in the second photo, this was new old stock, and included its original labels. My guess is that the thing comes from before the 1940s, because the addresses do not have postal zones. Basically, it is an aluminum frame with an asbestos pad. It hangs on the wall and you can store an iron there. As shown in the third photo, the cord wraps around the stanchion at the top. Thanks to the asbestos pad, you can even put your iron away when it is hot

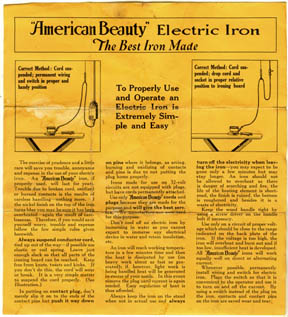

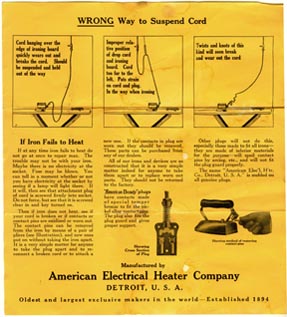

Here are some Hints on Ironing offered by the American Beauty company. Thanks very much to our friend Karen for sending these images.

Instructons for the American Beauty Iron

Click on the image to make it bigger

Thanks again, Karen!

Here is a peek into the Sunbeam factory where you can see the Ironmaster being made on an assembly line. These are real people working in a gritty environment -- no automation here.

The Assembly Line for the Sunbeam Ironmaster

Photograph by Frank Scherschel c. 1946

Click to enlarge

The last leg of this triangle came when I found a kit for a fold-away ironing board suitable for small apartments; my guess is that this comes from the mid 1940s because the addresses have postal zones, but not ZIP codes. The last two photos show all items in-place, Ironing Board, the "Wil-Stan," and the American Beauty Iron. It works VERY WELL!

The American Beauty Irons

The "Will-Stan" Iron Holder and the Ironing Center

Click to Enlarge

Recently, we got this note from one of our readers:

"... Hello Jitterbuzz,

I saw your web site with the mention of the Iron Rite "mangle" and the Wil-Stan iron holder. I would like to tell you that I am the proud owner of an IronRite machine. Also I am the grandson of the inventory of the Wil-Stan iron holder. This product was invented and manufactured in Akron, Silver Lake and Monroe Falls Ohio by the late Chester D. Stanley. The model on the cover of the box was my mother Margaret K Stanley. I am also the proud owner of a Wil-Stan Steam Iron holder.

Dennis Stanley ..."

During the 1940s, the US Government published a series of pamphlets on the proper operation of electrical appliances (these were a novelty in rural areas that were just getting electricity.) Here is an exerpt from the section on irons -- it suggests that one should always place the iron on an insulated surface to prevent fires.

1940s Guide to Using an Electric Iron

Click to enlarge

OK Now, let's look inside the American Beauty Iron

The Handle of the Iron

As you can see in the photos below, the handle is a very distinctive feature of the American Beauty Iron. The clear lucite center was very distinctive. Red and Amber variations were offered.

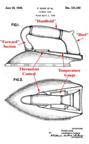

American Beauty Exterior Design

Click to Enlarge

Click here if you want to learn how to get Patent Drawings

Not only is the design of the handle distinctive, it is also patented. Frank Kuhn and Laurence H. Thomas are the creators of this marvelous gem, and received Design Patents 121,163 and 121,164 for this particular variation in June of 1940. However, the design is functional as well as attractive, as shown in the patent for the interior design

American Beauty Design Patents

Design Patents 121,163 and 121,164

Handle interior Patent No. 2,256,147

Click to Enlarge

Click here if you want to learn how to get Patent Drawings

There are three parts to the handle:

- The "Forward" section that supports the handle (labeled "A")

- The Lucite "Handhold" (labeled "C")

- The "Heel" or rear section that provides the connections (labeled "B")

The trickiest part of repairing an American Beauty is getting the back-plate off without cracking the Bakelite. I suggest using a small screwdriver to pry, emplacing it at the center of the back-plate at the bottom, while you push inward and upward with a thumb at the top. Be very careful and gentle. This is probably the only design flaw in the American Beauty Iron. The use of a press-fitting gives the iron a sleek, streamlined feel with no screws showing. However, over time, it is a virtual certainty that the cord will wear out, and hence there will come a time when the back plate has to come off.

The American Beauty company never changed this design. Here are some photos of a steam iron manufactured in the 1990s and they clearly show that the Kuhn and Thomas design has been kept, although the expensive lucite handhold has been replaced. And, you still have to pry on the back-plate to change the cord...

American Beauty 1990 Steam Iron

The Design Did Not Change from 1940-1990

Click to Enlarge

Most Iron handles work this way. The Rowenta iron had a screw to hold the back plate on. Some irons do without the "forward" portion, using a cantilever design. Other irons have moved the thermostat control from the iron base to the forward portion of the handle. Underneath, all these things work the same way.

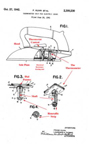

The Iron's Thermostatic Controls

The Thermostat looks complicated but is actually quite simple. It is based on the principle of the bimetallic strip -- the "sandwich" of metals with different thermal expansion properties (like Nickel, Manganese and copper). Because the two metals expand at different rates, the strip will curl or warp -- effectively translating heat into mechanical motion. In turn, the change in position due to the warping may be used to make or break a circuit. Research has developed bimetallic strips that warp in a linear fashion with temperature. Thermostatic control is achieved by setting the switch to reflect this warping.

In the American Beauty (and most other irons), this is achieved by the mechanism shown below. There are two contact points ("K", " K' ") that are made of spring steel. Normally, they are in contact at point "Q". As the bimetallic strip "H" heats up, it warps downward, eventually pulling " K' " away from "K", breaking the circuit and causing the current to stopr flowing to the resistance heater.

The Thermostat Knob is connected to a Cam ("S") that varies the distance between "K" and " K'", short distances for low temperatures and long distances for high temperatures. Thus, when a hot temmperature is desired, the bimetallic strip "H" must warp a lot more than when a low heat is desired. The iron will automatically be shut down when the contact points are separated. However, as soon as the iron cools, the bimetallic strip will "uncurl" and spring steel contacts will come together and the iron will start to heat again. This process will assure that the iron remains in the proper temperature range.

The precise alloys used in the bimetallic strip determine the precsion with which the temperature may be maintained. For the American Beauty Iron, the variance is about 20 degrees Fahrenheit.

The American Beauty Iron is unique in that it has a thermometer that shows the temperature of the sole plate.

American Beauty Iron Thermostat and Thermometer

Thermostat Patent No. 2,328,152

Thermometer Patent No. 2,300,230

Click to Enlarge

Click here if you want to learn how to get Patent Drawings

There was a time when automobiles had gauges that told you important things like the temperature of the cooling water and the oil pressure. These have been replaced by "idiot lights" that only come on when it is too late to do anything. Modern irons allow you to set the thermostat for various fabric types, but they don't have a thermometer, a sacrifice to cost-control in the same way that your job has been sacrificed to a far-away dictatorship.

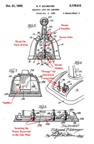

We leave our treatment of "normal" electric irons with a look at this Durabilt Travel Iron, Model FB. This is a small thermostatically controlled iron with a folding handle that could be easily packed for keeping clothes pressed while on the road. From the late 1920s through the 1940s, these irons were made by a succession of companies, beginning with Beardsley and Wolcott, then by the Winstead Hardware Manufacturing Company, then by the Durabilt Company and finally by the Singer Company -- the same folks who made sewing machines. My iron was made by the Singer company and probably dates from the mid 1940s.

Durabilit Iron with Original Box

Special Features of the Durabilt Travel Iron

Model 189B with a Thermometer

Patent No. 2,066,240

Click to Enlarge

Click here if you want to learn how to get Patent Drawings

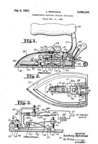

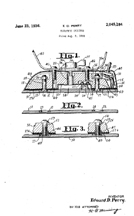

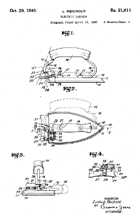

The basic design was first patented in 1931 by Edward D. Perry (Patent 2,045,284) but did not have the thermostatic control. The complete folding travel iron with thermostat was patented by Ludvig Reichold in 1937.

Durabilt Iron and Patents

Durabilt Travel Iron Patent No. 2,045,284 and No. RE 21,611

Click to Enlarge

Click here if you want to learn how to get Free Patent Drawings

Steam Irons

We remember that both heat and moisture are required for proper ironing. Ironing was usually done the day after washday. First the clothes had to be dampened by sprinkling with water, rolled and left to sit from one to 12 hours so that they would have just enough moisture for proper ironing.

The needs of commerce led to the use of steam in the ironing process to shorten the soaking period. In most cases, live steam was fed through the sole plate of the iron from an external boiler. This was an expensive proposition that was only feasible for large scale commercial applications. It was also quite dangerous, foming the basis for considerable black humor in physical comedy (e.g. The Three Stooges).

The technology of bringing steam to the home was not available until the 1930s. However, it should be noted that in the case of home ironing, "steam" refers to vaporized water in which tiny water droplets are distributed, and not water in which the entire liquid phase has been converted to gas. "Ironing Steam" is more like "condensing steam" and provides more moisture for the chemical reaction while having lower pressure and consequently less danger.

Among the very first home steam irons to be successfully marketed was the Steemelectric. It was basically a kettle with a polished, flat base. Water was boiled inside to produce the steam which was emited through the sole plate. There was no thermostatic control and it could not be used for dry ironing.

The first thermostaically controlled steam iron was the Steam-O-Matic model A-300, introduced in about 1941. The mechanical design was the work of Edward P.Schreyer; following this, a streamlined model B-300 with exterior designed by Brook Stevens was introduced to great success. The Schreyer design has largely been the basis for all subsequent steam irons.

Early Steam Irons

(left) "Steemelectric", (3rd) "Steam-O-Matic"

(2nd and 4th) : Schreyer Steam Iron Patent No. 2,178,512

Click to Enlarge

In order to emit "steam" onto the fabric to be ironed, an evaporation chamber is placed in contact with the heatable sole plate. A supply conduit conveys water from a tank to the evaporation chamber. The steam produced in the evaporation chamber exits the iron through openings in the ironing surface of the sole plate. In this early version, the steam jets were concentrated in the nose of the iron.

During the 1950s, there was a period of intense competition among manufacturers that was known as the "Holey Wars". Proctor began with an advertising campaign that touted the efficiency of its 15 steam jets. Eventually some manufacturers featured over 100 steam vents. The industry standard has evolved to be about 22 holes spaced evenly around the perimeter of the sole plate.

One of the problems associated with early steam irons was weight. The self-contained steam iron had to have a water tank which led to an increase in size and weight. Also, early steam irons could not be used for "dry" ironing. Other problems revolved around filling the water tank and getting it high enough to assure flow to the evaporation chamber. Many early steam irons used an external water reservoir that could be removed. Here are two examples:

These wonderful photos were sent by our friend 40s Phil out there in Indiana.

"...This is a Betty Crocker Iron from the late 40s. General Mills decided to jump into the lucrative appliance market right after WWII and came up with a line of about 5 or 6 appliances. This unique Steam/dry iron is a two piece outfit ...... just click the iron into the attachment and you've got a steam iron. GM got out of the appliance business just 5 or 6 years later so these Betty Crocker appliances aren't that easy to come by. I got this iron with the original box and all the papers and booklets...."

Betty Crocker Convertible Steam Iron

(l) Assembled (r) Disassembled

Paper Materials and Ad for the Betty Crocker Iron

Ad from the back cover of the Saturday Evening Post, 12-05-53

Click to Enlarge

Here's another General Mills Iron from the mid 1940s:

Mid 1940s General Mills Iron

Click to enlarge

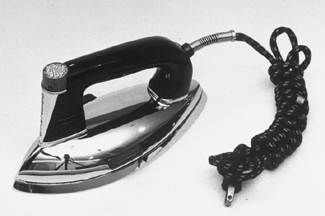

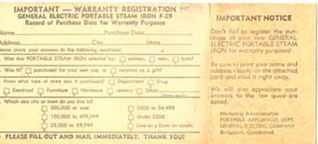

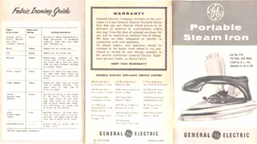

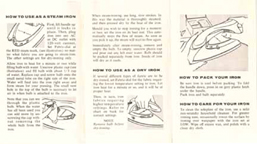

I found this iron at an estate sale just before Christmas, 2002. Indeed, Santa came early, because this never-been-used beauty was hiding in the attic in its original box just waiting for me at tossaway prices because it was the final hours of the sale. It's a General Electric Portable Steam Iron, Model F-29 (Catalogue 17F29). The detachable water container adds a very nice note to the little iron. I tested it and it works very well. This is a nostalgic memento from an era when you could actually pack an iron and not expect to be strip-searched by security.

GE (F-29) Portable Steam Iron and Warranty

Instructions for the GE (F-29) Portable Steam Iron

The little plastic cone is the water reservoir

Click to Enlarge

Here's another Travel Iron from the mid-1940s:

Mid 1940s Travel Iron

Click to enlarge

The Future

Probably the most reliable forecast of the future is that "ironing" as we know it will go away due to fabric treatments that eliminate wrinkles. We owe most of this technology to Ruth Benerito (born 1916) helped win the war on wrinkles with her invention of wash-and-wear cotton fabrics while working at the U.S. Department of Agriculture laboratories in New Orleans in the 1950s. Before this innovation, women spent hours and hours every week ironing clothes for their families. Benerito found a way to chemically treat the surface of cotton that led not only to wrinkle-resistant fabric, but also to stain- and flame-resistant fabrics.

The Remarkable Ms. Benerito, Goddess of Perma-Prest

Not everything is perfect, however. Ms. Benerito's technique uses formaldehyde-based reagents that have caused world-wide concern about their impact on human health and the environment.

Previously, one of the more effective formaldehyde replacements was an organic acid called butanetetracarboxylic acid (BTCA). But the exceedingly high cost of BCTA prevented its applications on a commercial scale.

Drawing on the BCTA technology, Dr. C.Q. Yang of the University of Georgia found that citric acid, while not effective itself, could be combined with two different polymers of maleic acid in a manner that would efficiently cross-link the cellulose fibers in cotton fabrics. The results of this synergistic action,is a cotton fabric with demonstrated superior durable press performance, good laundering durability, and high fabric strength retention. Because this new finish system is cost effective, it has become attractive as a formaldehyde replacement and is now under commercial development

For those items outside the scope of Perma-Prest, Jonathan Nwabueze from Guildford, England (UK) offers a novel solution. He got so fed up with ironing and being delayed in the morning because of last minute ironing that he invented an iron that works without the need for a board by using a heated vacuum to remove the creases from clothes. The 30-year old entrepreneur said "it can even smooth out wrinkled clothes while they are being worn, though its not recommended for obvious reasons and at the userís discretion!" Garments and other fabrics can be ironed whilst they are hanging or free-standing. It could also offer greater flexibility to the task of ironing, for instance in travel, outdoors or for large area fabrics.

Called the Jen Turbo Boardless Iron, it uses a small fan powered by an electric motor which draws the cloth towards its heated base, through a combination of direct suction and the lowering of air pressure between fabric and plate. Steam is generated in a chamber above the plate, which is blown onto and through the fabric by the internal fan to remove the creases. The steam is then re-cycled back into the body of the iron by the fan.

Here is a modern approach that combines Housework with Working at Home

Iron all your virtual clothes...

Underwriters Laboratory (UL) Standards for Irons

Just in case you wondered, here are the standards set by the Underwriters Laboratories for Irons.

- Drop test -- drops iron three feet onto an oak floor, once on each side, once on the point, once on the heel and once flat, while heated and unheated. Iron must continue to operate normally afterwards. No opening can be created that is big enough to allow a finger -- simulated by a plastic probe -- to enter the iron and touch a live part.

- Endurance test -- operates the iron for 500 hours.

- Flex test -- flexes the cord 50,000 times, 20 cycles per minute, to check cord integrity.

- Temperature test -- determines that no surface of the iron ever gets hotter than 662 degrees F, a condition that could cause a fire.

- Mold-stress test -- bakes it in an oven for seven hours at 18 degrees F higher than maximum operating temperature to check for structural integrity.

- Moisture test -- conditions the iron in a humidity chamber for 24 hours at 85 percent humidity.

- Overfill test -- overfills steam iron and lets water drip over the unit to check for shock hazard.

- Strain relief test -- pulls on the cord for one minute by suspending a 20 pound weight from it to simulate the effect of yanking on the cord.

- Stability test -- angles the iron on an inclined plane at 10 degrees to see if it will tip over.

- Flame resistance test -- applies direct flame for 30 seconds to determine that it will not support combustion.

- Leakage test -- checks for the presence of excessive current on the outside of the appliance.

- Power-input test -- determines that the iron draws no more than 105 percent of rated wattage.

Starch - The Old-Fashioned Way

Some of you vintage nuts may have dress shirts or detachable collars that require starching. You may have found that the lame stuff that comes out of spray cans doesn't do the job at all. If you want your shirts to look right, you have to get hold of Argo Gloss Laundry Starch (It is packaged in a distinctive maroon box with white edging/lettering).

Inside this package, you will find a fine white powder that lloks like (duh?) cornstarch or flour. [Does anyone under the age of 40 know what either cornstarch or flour look like???] Add about 3/4 a cup of cold water to 1/4 cup of this white powdered laundry starch, (mix with the tips of your fingers in a saucepan to remove any lumps), and then quickly pour on about a kettleful of BOILING water until you see the color change from white to opaque. Take it to your washer and add it to your rinse water. When the clothes have spun out, hang them to dry (Do NOT use the clothes dryer). Sprinkle the clothes lightly with water to activate the starch and then iron when barely damp. This will produce medium to moderately heavy starch in dress shirts, napkins, etc. The nice part about adding the starch mixture during the rinse cycle is that it distributes itself evenly in each layer of fabric --- thus, things that need to be heavily starched like collars and cuffs get a double dose because they are two layers thick. Try this at least once to get an idea of what laundry was like in the 1940s.

Michelle ,one of our faithfil readers has this suggestion:

"... If anyone ever boils starch for heavy hand starching, grate a little paraffin into it. It will make for easier ironing. This tip comes from Brittany (France) where they still starch their lace headgear, it was supposedly used by the nuns. I remember how stiff and shiny their coiffes were. ..."

Etymology of the Dreaded "M" Word

The Oxford English Dictionary defines a "Mangle" as a device that uses rollers for pressing or extracting water from clothes. It gives the origin of the word as Dutch, mangelstok.

I believe that current usage feeds on a myth that people could do serious damage to their hands if they were caught in the rolls. Every modern ironer that I have seen has a foolproof mechanical disengagement device. When I got my ironrite, it was set to balk at four layers of denim. I suspect that folks who were suspicious of the machines (or jealous of their owners...) preferred the old word "Mangle" rather than "Ironer."

On the other hand, it appears that none other than Herman A. Sperlich used the dreaded "M" word in his 1928 patent for the original Iron Rite. This was probably before he got a Public Relations Department...

Mr. Sperlich's 1928 Patent No. 1,670,387

The Dreaded "M" Word as Sanctioned by Uncle Sam, Himself!

Click to Enlarge

Join Us on Facebook

Home | About Lindy | 1940s Collectibles | Upcoming Events | Vintage Clothing

The Guide - Establishments - Travel - Accessories

Music | Links | Photo Gallery | Extras | Contact